Archives |

| September 2023 |

| August 2010 |

| January 2010 |

| November 2009 |

| April 2009 |

| March 2009 |

Seeing the light with SpotOn!

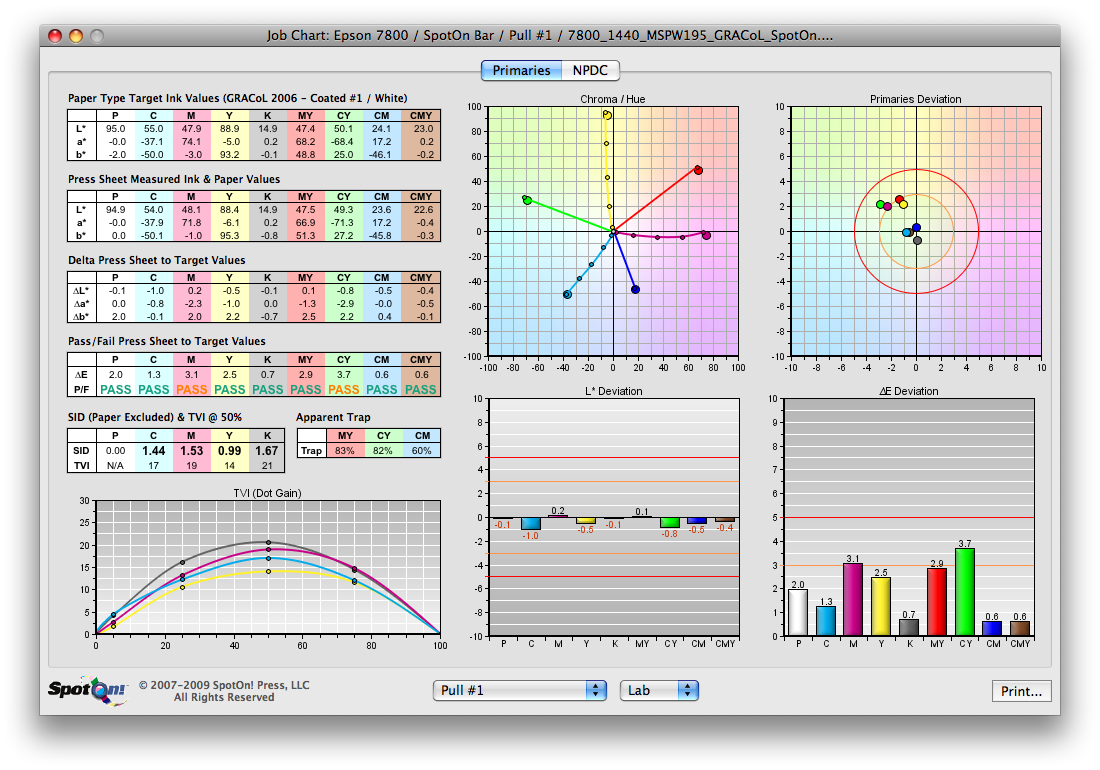

I've seen the light and now I must spread the word. Having gone through the very first GRACoL Expert class, I've been involved in the G7 process from the very inception and have done many Master Printer Qualifications and have created even more plate curves using this awesome process. Up until recently, I had been using handheld spectro-densitometers like the X-Rite 528 or the Techkon SpectroDens. While these devices made it possible to achieve the intended aim, there were some inherent limitations. Along came SpotOn! I have to say that doing a calibration run with a handheld device versus using SpotOn! is literally night and day, which is why I titled this blog seeing the light. SpotOn! comes with a colorbar that you measure directly with an i1 (or using ColorPort with any supported device) or import from a CGATS text file. Once you measure the bar, which takes all of 30 seconds, you chart the measurements and get ALL the feedback you need to nail the solids and overprints. I've been using my laptop and my i1 press-side during calibration runs and the results have been amazing. I have not used a better tool to establish plate curves for GRACol since I started using the G7 method 3 years ago. I will be happy to demonstrate this powerful software via WebEx for anyone that is interested. Check out the screenshot below to see all the feedback I was talking about.

10 comments

The question is: does spot-on and an i1Pro eliminate the need for a pressroom hand-held device during press calibration?

I am the distributor for Opaltone in Quebec. We use the handheld spectro-densitometers X-Rite to verify.

You are saying that spot on software can replace the hand held spectro-densitometers X-Rite for color calibration.

Would like to learn more.

Dan, do you use Spot On in place of Curve Tool? Forgive me, I don't know all of the functionality of the Spot On software. The Curve Tool seems to overshoot things a bit, and I was wondering if this would be a good replacement. I would love to have a demo sometime.

Pretty busy screen but it does seem to capture everything one would need.

Be interested in knowing how well your i1 agrees with your Techkon or 530. I've reported on some differences between scan mode and spot mode with the i1-IO system. What is your experience?

To Chris Hamilton:

No, SpotOn! is not a replacement for the IDEALink Curve software. SpotOn! simply reports on printing conditions but doesn't offer any direct corrective measures although some degree of correction can be inferred from the charts/graphs it gives you (there's another screen that is specific to G7 metrics such as NPDC tone curve and gray balance).

Having said that, I feel SpotOn! provides better reporting information than IDEALink Curve itself.

-Terry Wyse

To Marc Levine:

The typical way you would use SpotOn! is to place one or two of it's special targets in line vertically with a couple of ink keys on the press form and then focus on those with your Eye-One measurments. Once you get the numbers you're looking for, you then take the information from those couple of ink keys and then use your hand-held or scanning spectro to set the rest of the ink keys.

So, no, SpotOn! + Eye-One would not replace the hand-held/scanning spectro. Besides, SpotOn! is not intended to be used for monitoring production press runs although I suppose it could be used for that. The better use for production would be to pull press sheets from a run and enter them in SpotOn! after the fact and for documenting day-to-day production.

-Terry

I'm commenting on several of the posts. Andrea asked whether SpotOn! can replace a handheld device for color calibration. I would say "Yes" in that it has replaced a handheld in my approach to establishing G7 plate curves. Now, having said that, many pressrooms still use handheld devices for production make ready and SpotOn! does not and will not change that aspect. SpotOn! is great for establishing exactly what SID is required to achieve accurate solids and overprints. You can continue to use a handheld device and run to the SID's established by SpotOn! for make ready.

SpotOn! is not a competitive solution to IDEALink Curve but rather a compliment to it. With SpotOn! I can rest assured that I am feeding good data into Curve. And Curve generates better curves with good data. The two products work well together and I would recommend that anyone who has invested in Curve take a close look at SpotOn!

And to Danny's comment about instrument agreement. I have found it to be reasonably close. Usually I will figure out exactly what the density difference is between my i1 with SpotOn! and the clients measurement device and figure in the difference but it is usually nominal.

So you are mainly using this as a solid ink density assessment tool - even though the display has all kinds of color data displayed. The User Interface provide density information in a more digestible format. The density readings are not significantly different that you would have obtained with the handheld densitometer.

Are you using the i1 in its accelerated mode - scanning through the template those 30 patches?

Answering Danny's post: I am using an i1, in strip mode, to scan the SpotOn! control strip. I am using SpotOn! to find out what Solid Densities I need to run to meet the GRACoL Specification for solid colors (CMYK) and overprints (RGB) - which are only specified in LAB. So I'm looking at the color graphs and once I get everything in tolerance I reference the density and that becomes the "house standard" SID's for pressman to use for make-ready.

I have to second Dan's experience with SpotOn!

Bruce was kind enough to offer me a temp license so I could use SpotOn! for a week-long G7 gig I did this week (as I write this, I'm chillin' in my hotel room after a long of being in the pressroom). I suspected the product was good as I'd seen it back in it's Excel days but I had no idea it was going to be THAT good. I barely pulled out my trusty SpectroEye the entire week and only to confirm that SpotOn! plus my EyeOne were giving me good data (when you've used device such as the SpectroEye for as long as I have and have come to trust it's accuracy, it's kind of hard to let go).

Bottom line, we had GREAT success this week profiling two presses on three different stocks and two different screen rulings. I owe a lot of that success to SpotOn! It also proved to be an awesome presentation tool for the wrap-up meeting we had with the owner, pressroom supervisor and two of the lead people in prepress.

The icing on the cake was that I easily sold my first copy of the software even though it was never part of the original proposal.

Terry Wyse